Vibration Monitor

Vibration Monitors are powerful online monitoring and diagnostics systems. They have been designed to increase the reliability of strategic rotating machinery.

Description

The Vibration Monitor systems can operate as an independent monitoring system or they can be used as extension of an existing protection system.

The Vibration Monitor software is designed for the control of the data collection and archiving. Setting up the program allows to easily configure the required measurements.

The software enables the real time online display of the current measurement values on the predefined channels.

The DDS software system is designed for the follow up processing and archiving of all the collected data. The setting and control of all Vibration Monitors is done in DDS software. The setting has never been easier. The only thing which needs to be done is to create the tree of machines, measurement points,required readings and assign them to appropriate channels. Then you just press START and the readings are done automatically. Data acquisition Data acquisition can be done conventional with fixed defined time intervals. Some important value changes in between those measurements can been lost with this method. Every measured data is saved, so the values with no information (same value as before) are saved and take valuable space. To improve this we have developed a new Adaptive Algorithm of Data Acquisition. Data are measured continuously, so nothing can be missed out. But only selected values are saved. If the measured value is not changing significantly, it is not saved. Adaptive Algorithm selects which data to save and which not. Single Vibration Monitor modules can be easily composed together creating a wide channel system. Different versions of the Vibration Monitors can be mixed together in one system all controlled by one software on one computer.

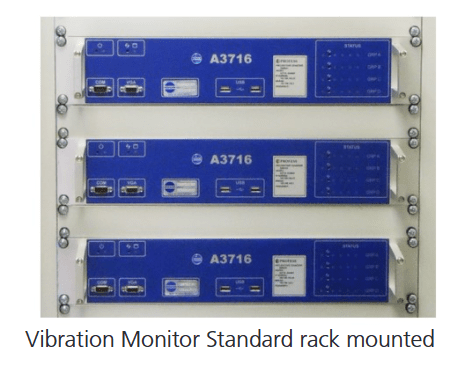

Vibration Monitor Standard (2U)

The Vibration Monitor Standard system contains 16 AC, 16 DC and 4 TACHO inputs. All channels are measured simultaneously. The Standard version only needs 2 Slots (90 mm height) in your 19” aluminium rack.

› The set up and control of the Online units is done by the Data Manager.

The set up has never been easier. Storage of data and evaluation is

handled with the DDS software.

› The new data acquisition control system was developed for the

Vibration Monitor. Now the unit reads the vibration continuously, not

only at predefined time intervals. The adaptive algorithm saves the

readings to the database as needed.

› The Vibration Monitor unit continuously monitors the required

machines and adaptively saves the readings to the data storage

computer. The data is accessible from various workstations for control

and analysis.

› The great advantage of the DDS software is its very easy set-up. There

is no difficult installation of the server anymore and no complicated

set-up of parameters. The demands for transfer and data storage

are minimized.

Key Features VM Standard / Plus

• 16 x 4-20 mA (Plus)

• 16 channels AC

• 16 channels DC

• 4 TACHO inputs

• 16 BNC buffered outputs of signals from sensors (plus version only)

• 16 programmable relays outputs (plus version only)

• Adaptive algorithm of data acquisition

Additional information

| Brand |

|---|

The information contained herein is subject to change without notification.

Typical properties may vary slightly.